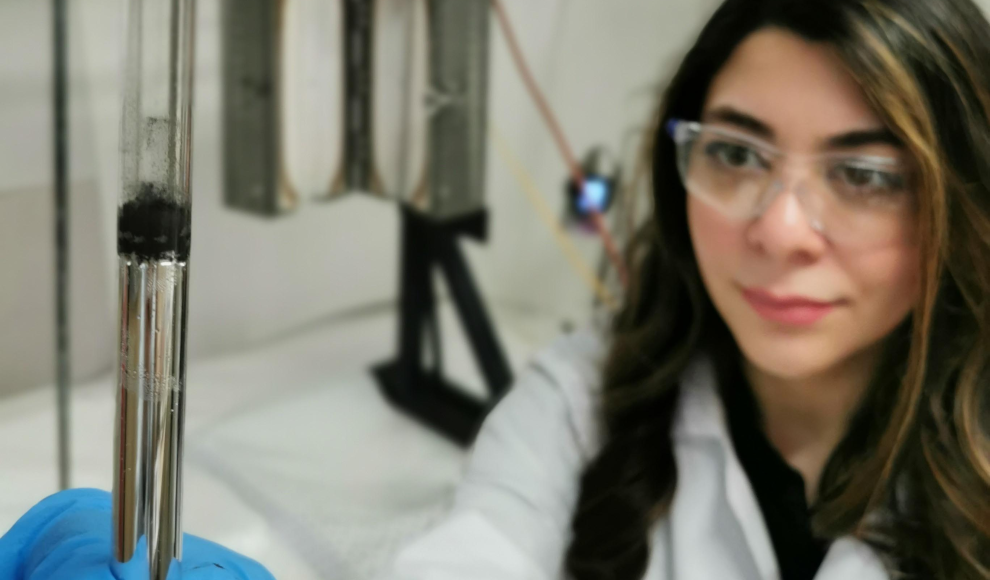

A new method for carbon dioxide capture has been developed by scientists at the Royal Melbourne Institute of Technology (RMIT) in Australia. The process involves using a liquid metal catalyst, eutectic gallium-indium alloy (EgaIn), which is heated to 100-120 degrees Celsius. Carbon dioxide is then passed through the cylinder, and the catalyst breaks down the molecules, forming solid carbon flakes that float on the liquid metal and can be easily removed. The main advantage of this method is that it produces solid carbon, which can be stored safely and indefinitely, avoiding potential leakage problems. The carbon flakes can also be used as a building material or further processed.

Carbon capture and storage (CCS) is a crucial technology for reducing greenhouse gas emissions and mitigating climate change. However, current methods are not yet capable of fully eliminating emissions in some industries. The new method developed by RMIT offers a promising solution, as it can be easily integrated into industrial processes and produces a useful byproduct. The low temperature required for the process also makes it compatible with renewable energy sources.

The RMIT scientists have patented the method and partnered with Australian company ABR to build a prototype plant in the size of a standard container. The success of this project could have significant implications for the future of carbon capture and storage, as it offers a more efficient and sustainable method for reducing emissions. The potential for using the solid carbon flakes as a building material also opens up new possibilities for carbon utilization and circular economy.