In a world where electronic waste is becoming an increasingly critical issue, scientists at the Karlsruhe Institute of Technology (KIT) have developed a fully biodegradable display. The display works using the electrochromic effect of organic materials, which changes the light absorption and alters the color of the display when under tension. The researchers believe that the display could be used in the medical industry, where it could be integrated into sensors and then composted after use.

The integration of electronic components into everyday objects and new technologies such as the Internet of Things (IoT) is expected to lead to even more electronic waste in the coming years. This is particularly concerning given Germany’s low recycling rate of just 15.8%. As a result, scientists are searching for sustainable alternatives that can save resources and reduce waste to protect the environment. The KIT researchers’ biodegradable display could be a significant step forward in this effort.

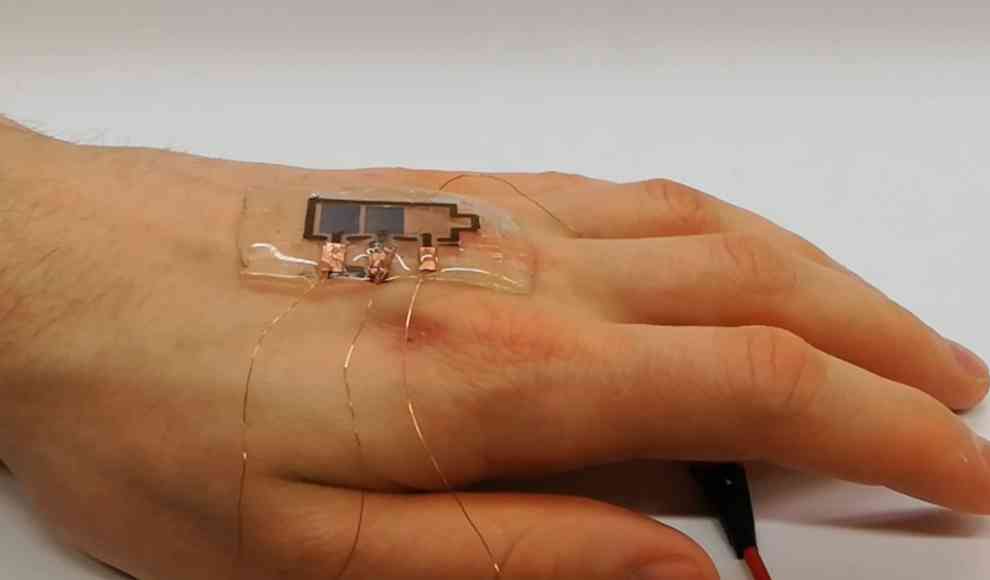

The display’s architecture is much simpler than that of traditional LEDs and LCDs, making it possible to produce it using inkjet printing. This means that it could be cost-effective and material-efficient to produce customized displays on an industrial scale. The display’s low power consumption also makes it an attractive option for use in the food industry and medical fields. In areas where hygiene is crucial, the display could be composted after use, rather than requiring extensive cleaning. In the food industry, the display could be used in combination with quality monitoring sensors to show the product’s shelf life. Thanks to the digital printing process, the display could be easily customized to fit the packaging without requiring complex process changes.

Overall, the KIT researchers’ biodegradable display could be a game-changer in the fight against electronic waste. Its potential use in the medical and food industries could help reduce waste and improve hygiene standards, while its simple architecture and low power consumption make it an attractive option for industrial-scale production.

Manuel Pietsch, Erstautor der Publikation und Forscher des Lichttechnischen Instituts (LTI) des KIT am InnovationLab in Heidelberg: ?Unsere Entwicklung konnte zum ersten Mal zeigen, dass es möglich ist, nachhaltige Displays aus überwiegend natürlichen Materialien mithilfe industriell relevanter Fertigungsmethoden herzustellen. Sie tragen nach Gebrauch daher nicht zum Elektroschrott bei, sondern können im Gegenteil kompostiert werden. Dies könnte in Kombination mit Recycling und Wiederverwendbarkeit dazu beitragen, einige der Umweltauswirkungen von Elektroschrott zu minimieren oder ganz zu verhindern.?