In a groundbreaking discovery, researchers have found a more efficient and environmentally friendly alternative to the traditional cooling process used in refrigerators and air conditioners. The conventional method, which relies on a closed loop system and a compressor, accounts for approximately one-fifth of the world’s electricity consumption. However, scientists from the United States and China have turned to the elastocaloric effect, a process that uses tightly twisted fibers to cool down when expanded. The researchers have already developed a prototype refrigerator using this method, which was able to cool a stream of water by almost eight degrees Celsius.

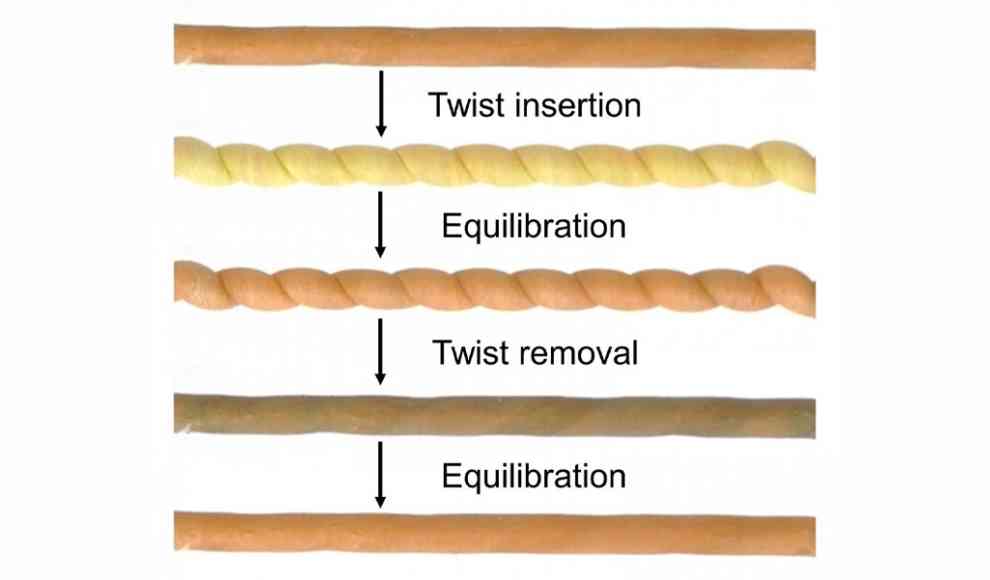

The elastocaloric effect has been known since the early 19th century, but it was only recently that scientists discovered its potential for cooling. The fibers used in the process are made of materials such as nylon, rubber, or a strong nickel-titanium alloy, and they cool down by up to 20 degrees Celsius when expanded at a rate of 50 revolutions per centimeter per second. The most efficient fibers were found to be those made of nickel-titanium, which cooled down the most. The researchers believe that this method could revolutionize the cooling industry, as it is much more efficient and environmentally friendly than the current method.

According to Ray Baughman, a professor at the University of Texas at Dallas, the elastocaloric effect works by changing the fibers from a low-entropy phase to a high-entropy phase when they are expanded. The researchers have already developed a prototype refrigerator using this method, which was able to cool a stream of water by almost eight degrees Celsius. The next step is to test the method with different materials and to see if it can be scaled up for commercial use. If successful, this could be a major breakthrough in the future of cooling methods, as it could significantly reduce energy consumption and help combat climate change.