A new breakthrough in the production of graphene has been achieved by researchers at the Karlsruhe Institute of Technology (KIT) in Germany. Graphene, a wonder material with unique properties, is currently produced almost exclusively from graphite. However, the KIT team has developed a new conversion process that allows graphene to be produced from carbon dioxide (CO2) found in the air. This new method could have significant implications for the production of graphene, which is used in a wide range of applications, including as a basis for quantum computers and in clothing to protect against insect bites.

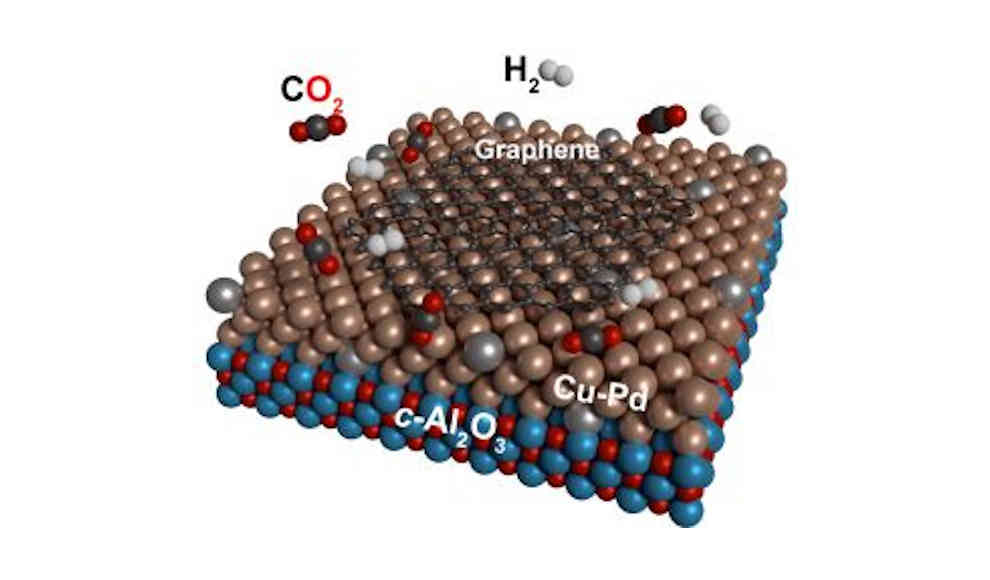

Scientists around the world are searching for ways to turn the harmful greenhouse gas CO2 into new raw materials. Recent innovations include a Finnish startup that uses solar energy to produce food from CO2, and researchers at ETH Zurich who have developed a demonstration plant that uses solar energy to produce kerosene from CO2 in the air. The KIT researchers have now presented a new conversion method in the journal ChemSusChem that uses CO2 as the starting material for the production of graphene. The process is based on the photosynthesis that occurs in plants, which converts light, water, and CO2 into biomass. The researchers use a metal-based enzyme called RuBisCo to convert CO2 into graphene at temperatures of up to 1,000 degrees Celsius.

The KIT team has successfully produced graphene with multiple atoms thickness, which can be used in batteries, filter materials, and electronic components. Further research is needed to determine whether the graphene produced using this method can be used to create functional electronic components. The new conversion process could have significant implications for the production of graphene, as it offers a more sustainable and environmentally friendly method of production. The KIT researchers hope that their work will inspire further research into the use of CO2 as a raw material for the production of other materials.