Scientists at Washington State University have developed a new method of producing kerosene and diesel from plastic waste. The plastic is first ground into rice-sized pieces and then mixed with activated carbon, which acts as a catalyst when heated. The polymer chains in the plastic are dissolved, creating a hydrocarbon mixture that is also found in airplane fuel. The resulting liquid product is a mixture of 85% airplane gasoline and 15% diesel. The process could be used on an industrial scale to create an alternative to fossil fuels and solve the recycling problem of plastic waste.

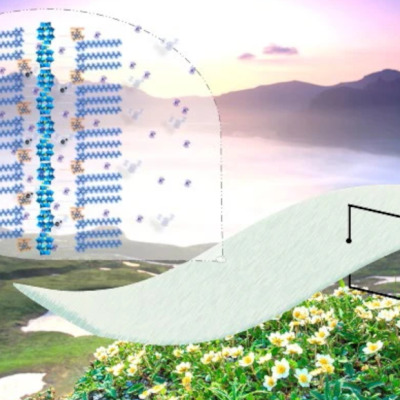

The researchers used PET bottles, plastic bags, and other plastic waste for their experiment. The plastic was ground into small pieces and mixed with activated carbon before being heated to 430-580 degrees Celsius in an oxygen-free environment. The catalyst accelerated the chemical reaction, breaking down the plastic polymers into small hydrocarbons. The resulting liquid product is a mixture of hydrocarbons that are typical of airplane fuel. The composition of the liquid can be regulated by changing the temperature and acidity. The resulting liquid product is a mixture of 85% airplane gasoline and 15% diesel.

The process has the potential to create an alternative to fossil fuels and solve the recycling problem of plastic waste. The resulting liquid product is of high quality, and the gases produced as byproducts are also of high quality. The activated carbon used in the process is not consumed and can be reused. The process has been tested only in the laboratory, but it has the potential to be used on an industrial scale. In the future, this process could be used to create a more environmentally friendly aviation industry and solve the problem of plastic waste.