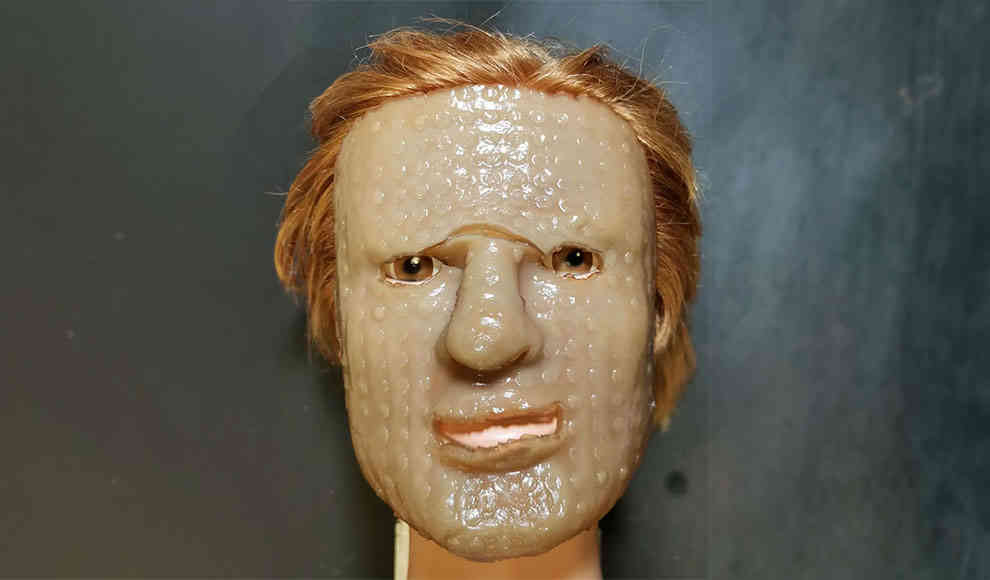

A new hydrogel mask created by 3D printing technology has been developed to reduce the pain and speed up the healing process for burn patients during regular dressing changes. The University of Waterloo in Canada has developed an innovative wound dressing material based on hydrogel to address the issue of frequent dressing changes that cause severe pain for most burn patients. The new wound dressing can be customized to fit the patient’s form using a 3D printer, and has a finely tuned surface adhesion that allows it to stick easily to the skin and be removed without causing pain. The material is made from a biopolymer derived from seaweed, a thermally reactive polymer, and cellulose nanocrystals.

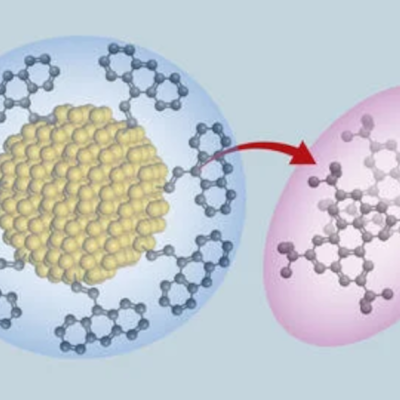

The researchers used 3D scanning technology to customize the dressing to the patient’s individual needs, allowing it to fit perfectly even on difficult surfaces such as fingers and noses. The dressing is designed to warm up when in contact with the skin and cool down to room temperature when removed, making it less painful to take off. It also releases medication over a longer period of time, providing sustained pain relief. The material has potential applications in cancer therapy, where it could be used to release medication outside of a clinical setting, and in the beauty and cosmetic industry, where it could be used to create personalized hydrogel masks enriched with specific facial and skincare products.

The hydrogel mask has the potential to revolutionize the way burn patients are treated, reducing their pain and speeding up the healing process. It is a significant breakthrough in the field of wound dressing materials, and its potential applications in other areas such as cancer therapy and the beauty industry make it an exciting development. The use of 3D printing technology to customize the dressing to the patient’s individual needs is a particularly innovative aspect of the material, and could pave the way for further developments in personalized medicine.