A new process has been developed that can produce pure hydrogen from toxic hydrogen sulfide. The process is set to be tested on an industrial scale soon. Hydrogen sulfide is produced in environments with low oxygen levels, such as in wastewater, sludge, and biogas production. It is also produced in the oil and paper industries, as well as in many other chemical processes. Currently, hydrogen sulfide is separated from other gases and converted into elemental sulfur using the Claus process. However, scientists at Ohio State University have developed an optimized process that can produce hydrogen from hydrogen sulfide.

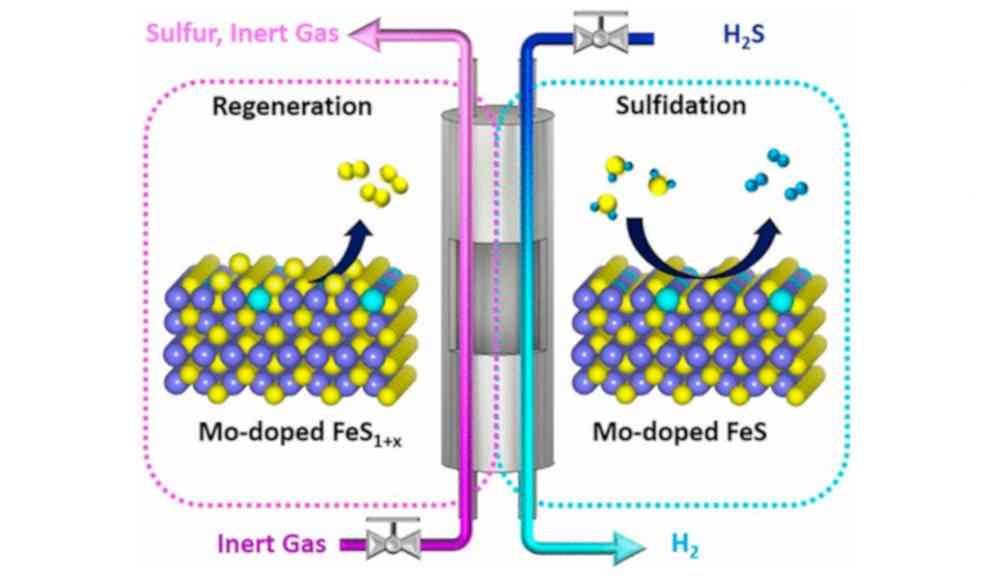

The new process is based on the chemical looping process, which uses metal oxides as catalysts and carriers. The scientists modified the process so that iron oxide binds to sulfur, which is then separated through a second reaction, allowing for the direct production of pure hydrogen. To make the process even more efficient, the iron oxide was doped with two percent molybdenum, resulting in a 24 percent increase in sulfur uptake. The team hopes to conduct industrial-scale tests of the process soon.

This new process has the potential to replace current methods of hydrogen production and provide a valuable product from a toxic gas. The team is continuing to work on optimizing the process to make it even more efficient.