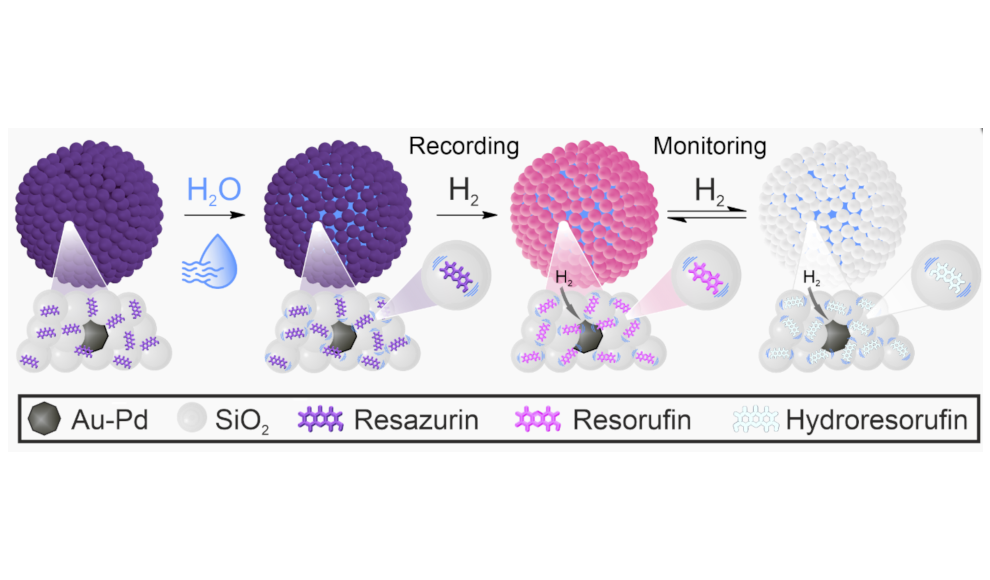

A new sensor made of supraparticles has been developed by scientists at the Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU) in Germany to detect the presence of hydrogen gas. Hydrogen is a clean and sustainable energy source, but it is also colourless and odourless, making it difficult to detect when it leaks. This is a problem because hydrogen can react explosively with oxygen in the air. The supraparticle sensor is made up of particles between one and ten micrometres in size, containing a violet dye called resazurin as an indicator. When the particles come into contact with hydrogen, the dye changes colour, providing a visible warning of a leak. The sensor works in two stages, with one stage being irreversible and the other reversible. The irreversible stage turns the sensor pink when it comes into contact with hydrogen, indicating that hydrogen has leaked from a tank. The reversible stage shows whether hydrogen is still leaking or not. If the tank is still leaking, the sensor will turn colourless again, but if there is no more contact with hydrogen, it will turn pink again.

The supraparticle sensor is made up of three components: a porous silica framework, a small amount of the indicator dye, and gold-palladium nanoparticles that act as a catalyst. The combination of these components and the porous structure is crucial to the sensor’s effectiveness. The sensor’s small size makes it suitable for use in many areas, such as coating hydrogen pipelines. The combination of irreversible recording and real-time spatial monitoring makes the technology attractive to industry. The sensor’s ability to detect leaks immediately is a significant advantage, as it can prevent accidents and save lives. The supraparticle sensor is an innovative solution to the problem of detecting hydrogen leaks, and it has the potential to make hydrogen a safer energy source for the future.