In a groundbreaking development, scientists at the University of Pennsylvania have created micro-robots made of iron oxide nanoparticles that can physically and microbiologically clean teeth. With approximately 3.5 billion people globally suffering from poor oral hygiene and irregular prophylactic treatments, these robots could revolutionize dental care. The interdisciplinary collaboration between dental and engineering researchers was born out of a coincidence. While dental researchers were studying the catalytic effect of iron oxide nanoparticles in killing bacteria that cause cavities, engineers were working on building magnetically controlled micro-robots from the same material. When the two groups discovered their projects overlapped, they decided to work together to develop a robot system that could improve oral hygiene.

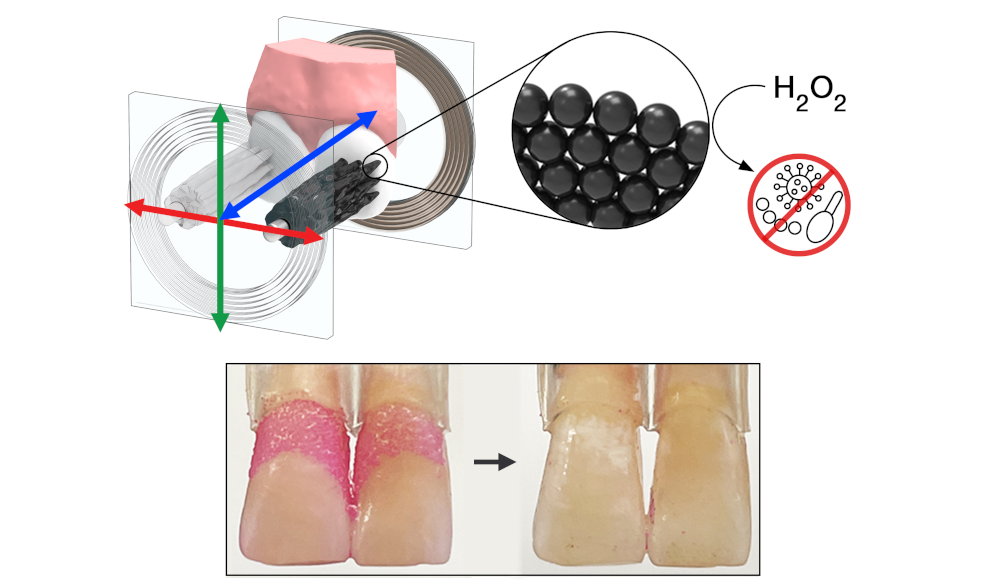

The micro-robot system can take on various shapes and replace toothbrushes, dental floss, and mouthwash. The robots can be programmed to automatically assemble the nanoparticles and control their movements, similar to a robotic arm that can clean surfaces. The system can also produce antimicrobial substances in the mouth to fight bacteria and prevent gum disease and cavities. The robots can adapt to different surfaces, reaching all corners of the mouth, even in cases of severe dental misalignment. In experiments with 3D-printed tooth models and real human teeth, the researchers found that the antimicrobial substances effectively killed problematic bacteria without damaging teeth or sensitive gum tissue.

The researchers plan to optimize the system further by using a variable magnetic field to control the micro-robots’ movements and determine the stiffness and length of the bristles. Once the system is optimized, clinical trials with humans will follow. The use of iron oxide nanoparticles in medicine is already approved by the Food and Drug Administration (FDA), making this development a promising step towards improving oral hygiene and dental care.