A new battery has been developed that can absorb CO2 from the air while charging. The cost per ton of greenhouse gas absorbed ranges from $50 to $100, depending on the application, due to the simple manufacturing process. The developers see potential uses in filtering power plant and industrial emissions. With the Earth’s atmospheric CO2 concentration recently reaching its highest level since the 1950s, scientists worldwide are seeking ways to reduce the concentration of CO2 in the air and limit the effects of climate change. The new battery technology developed by Sahag Voskian and Alan Hatton of the Massachusetts Institute of Technology (MIT) offers a more efficient approach to Direct-Air-Capture technology, which has been criticized for its high energy consumption and low effectiveness.

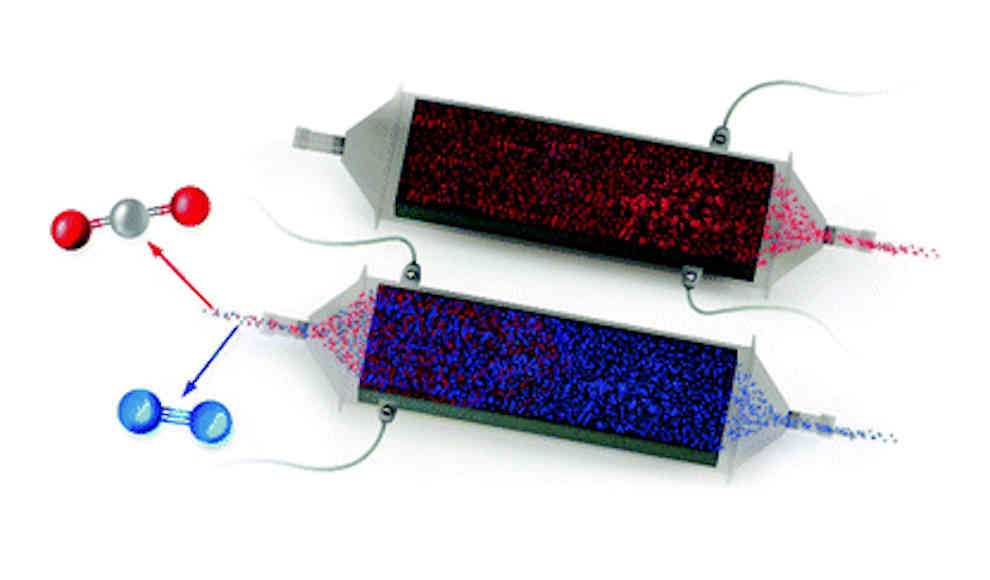

The battery’s cathode layer is made of a composite material consisting of ring-shaped hydrocarbons and carbon nanotubes. When the battery charges, the cathode layer takes in electrons and reacts with the CO2 in the air flowing through the cells. The electrons come from the anode layer, which is made up of nanotubes with ferrocene. When the battery discharges, the cathodes lose their CO2 affinity, and the bound carbon is released as pure CO2 gas. The battery’s specific chemistry releases nearly 100% pure CO2, and the energy required per captured mole of CO2 ranges from 40 to 90 kilojoules. The technology can be used for both the CO2 concentration in the air and significantly higher concentrations found in industrial plant chimneys.

The battery’s electrodes can be produced using existing mass production methods, and a slight adjustment to the manufacturing process could reduce costs to a few US dollars per square meter. The technology’s potential uses include filtering emissions from industrial plants and power plants, and a combination of several batteries that are charged and discharged in an anticyclical manner could ensure continuous separation of CO2. Voskian and Hatton have founded a company to commercialize the technology, and a large pilot plant will be built in the coming years for demonstration purposes. Scaling up the technology is not a problem, according to Hatton, who explains that “if you need more capacity, you just need to use more electrodes.”