A new galvanic process has been developed that could make photovoltaic cells cheaper by eliminating the need for silver. The high cost of silver, which is used in contacts and conductor tracks, has been a major factor in slowing the expansion of solar cell production. The solar industry uses around 15% of the world’s silver production, and as demand for the metal increases in other industries, such as electric vehicle production, the price of silver continues to rise. Scientists at the Fraunhofer Institute for Solar Energy Systems ISE have developed a process that replaces silver with copper, which is cheaper and more readily available. The researchers have also developed a process that uses recyclable aluminum instead of non-conductive polymers for masking.

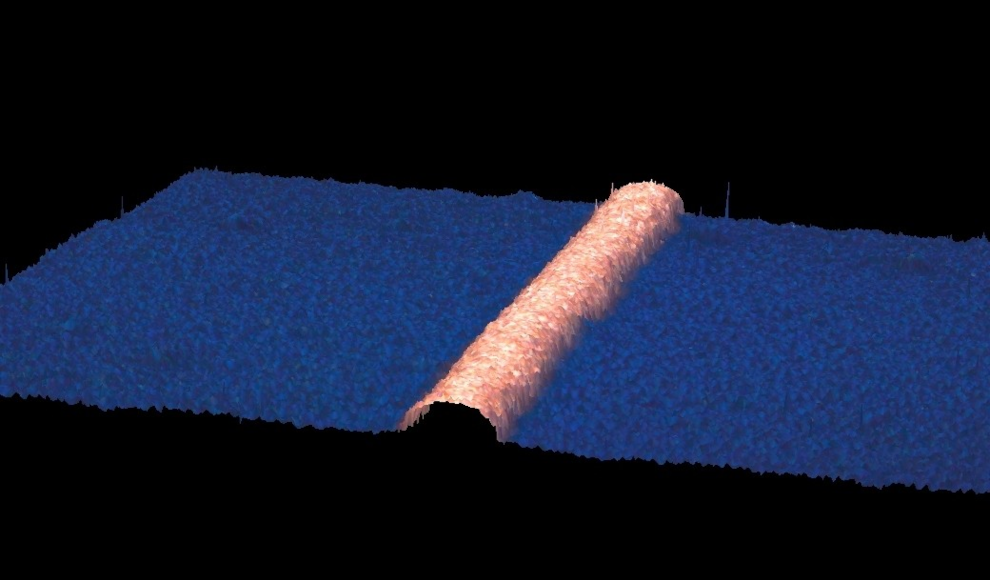

The new galvanic process developed by the Fraunhofer Institute for Solar Energy Systems ISE replaces silver with copper, which is cheaper and more readily available. The researchers have also developed a process that uses recyclable aluminum instead of non-conductive polymers for masking. The use of copper instead of silver for conductor tracks increases the efficiency of photovoltaic cells, as the copper tracks are thinner and cause less shading of the silicon layer. The use of recyclable aluminum for masking eliminates the need for expensive and non-recyclable polymers. The new technologies could make photovoltaic cells cheaper and more sustainable, and the high recyclability of copper and aluminum could help the industry move towards a circular economy. The researchers have founded a spin-off company, PV2+, to bring the new technologies to the industry, and a pilot production is planned for early 2023. The innovative solar cells are an important step towards a future powered by renewable energy.