A new CO2 absorber made from pyrolyzed plastic waste has been developed that can remove greenhouse gases from exhaust fumes in an energy-efficient and cost-effective manner. Currently, CO2 emissions from gas and coal-fired power plants are typically removed from exhaust fumes using a process called amine washing. The carbon dioxide is absorbed by various ethanol amines, which are alcohols with an NH2 group. While this method is popular in industry because it can be retrofitted into existing facilities, the amines break down over time and must be replaced continuously. Additionally, a temperature of around 100 degrees Celsius is required to release the bound CO2 from the amines so that they can be reused, reducing the efficiency of thermal power plants by up to 30 percent.

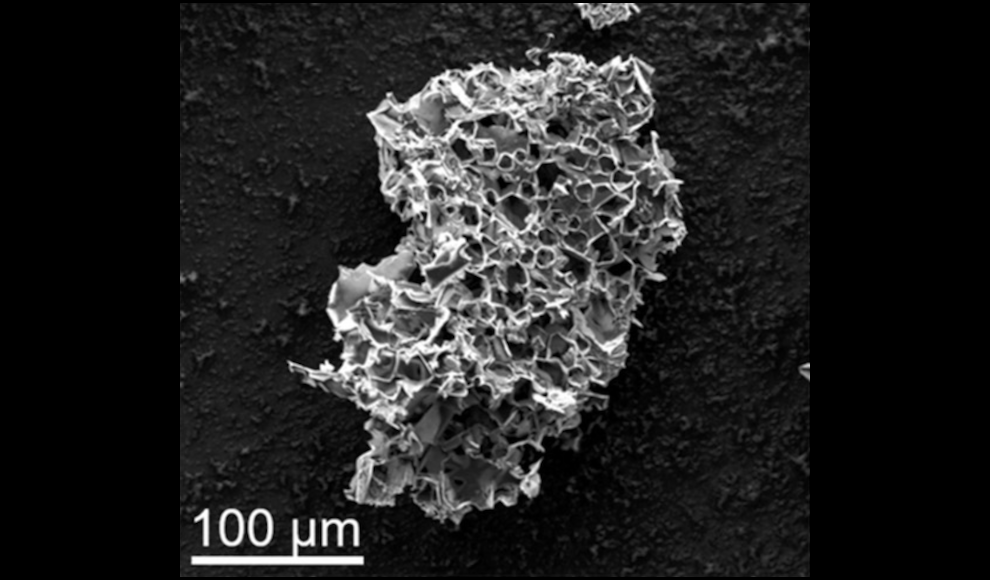

Scientists at Rice University have now presented a new method in the journal ACS Nano, in which CO2 is expelled at much lower temperatures. The material used in this process can be obtained from plastic waste. The plastic is ground into a fine powder and then heated for 45 minutes at 600 degrees Celsius under an oxygen-free atmosphere, a process known as pyrolysis. Potassium acetate particles, the potassium salt of acetic acid, are then added to the powder, resulting in a material with pores measuring only 0.7 to 1.4 nanometers in size. According to the chemists led by James Tour, this material can absorb between 16 and 18 percent of its own weight in CO2 at room temperature. To regenerate the innovative material, the absorbed CO2 can be released at 70 to 80 degrees Celsius, requiring significantly less energy than the amine washing process. Additionally, the system can be made from plastic instead of much more expensive metal due to the lower temperatures required.

The developers also claim that the plastic powder sorbent has a significantly longer lifespan than amines. The cost of removing one ton of CO2 from concentrated sources such as power plant exhaust fumes is approximately $21 using this new method, compared to $80 to $160 using amine washing. This new technology has the potential to revolutionize the way we remove CO2 from exhaust fumes, making it more efficient, cost-effective, and environmentally friendly.