Researchers at Concordia University in Montreal have developed an innovative 3D printing process that can build objects inside the human body. The Direct Sound Printing (DSP) technique uses a resin that is cured with sound waves, specifically Polydimethylsiloxane (PDMS), a polymer based on silicon. The liquid polymer is placed in a container and ultrasound waves are sent through a transducer, creating small bubbles that vibrate at high speeds. This causes a temperature of 14,727 degrees Celsius and a pressure of over 1,000 bar to be reached in the bubbles, which is enough time for the PDMS to solidify. The DSP 3D printer’s ultrasound transducer moves on fixed paths, building the object pixel by pixel.

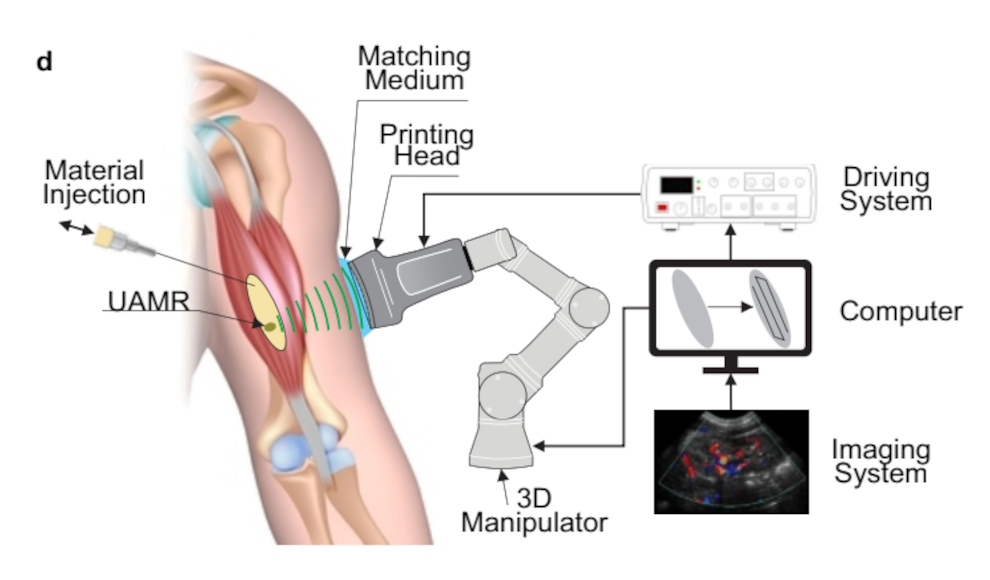

“We have found that if we use a certain type of ultrasound with a certain frequency and power, we can create very local, very focused chemically reactive regions. The bubbles can be used as reactors to stimulate chemical reactions that convert liquid resin into solid or semi-solid material,” explains Mohsen Habibi, one of the researchers. Depending on the duration of the ultrasound wave frequency and the viscosity of the starting material, objects with different properties can be printed. The developers see possible applications of the process mainly in medicine. An implant could be printed directly in the body using DSP. The building material is injected into the body and then solidified with the ultrasound transducer. PDMS is non-toxic and is already used in medications. The researchers have also demonstrated that ceramics can be processed with DSP.

The next step for the researchers is to try polymer-metal composites and eventually print metal using this method. The DSP 3D printing process is a significant breakthrough in the field of medicine, as it allows for the creation of implants directly in the body, reducing the need for invasive surgeries. The use of non-toxic materials also ensures that the process is safe for patients. The possibilities for this technology are endless, and it will be exciting to see how it develops in the future.