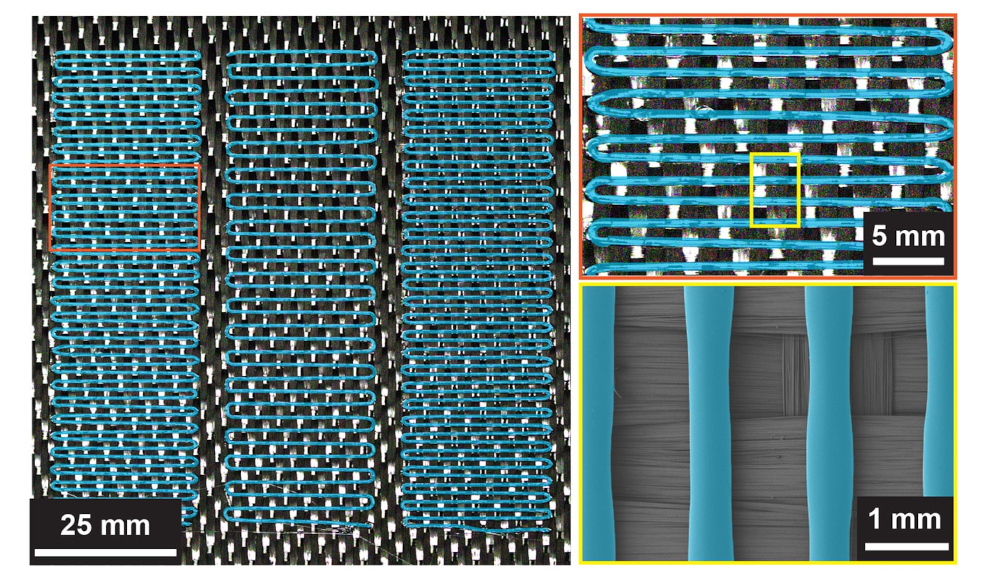

A new composite material has been developed that can self-repair using a thermoplastic healing agent, significantly increasing the lifespan of wind turbines. Laminated composite materials are used in wind turbines, hulls, wings, and many other products. They consist of fiber mats, such as carbon and glass fibers, bonded with plastic. Typically, these composite materials suffer damage from the detachment of several layers (delamination). Researchers from North Carolina State University, the Israel Institute of Technology, and the University of Houston have now developed a composite material that can self-heal, preventing delamination. According to their publication in the journal Nature, the researchers led by Jason Patrick printed a thermoplastic healing agent onto the fiber mat and integrated thin heating layers into the composite material. When electricity flows through the heating layers, they warm up, melting the healing agent. It can then close small cracks and other minor damage in the composite material.

The researchers found that this process can be repeated at least 100 times while maintaining the effectiveness of self-healing. They do not know where the upper limit is, if there is one. The biggest advantage of the self-healing composite material is that even complex structures can be repaired on-site without downtime. Additionally, the heating layers and thermoplastic healing agent are made of materials that are inexpensive and readily available. Compared to conventional composite materials, the production of the new self-healing composite material is only slightly more expensive. However, the longer lifespan of the material offsets these additional costs. The new composite material can significantly increase the lifespan of heavily stressed components, such as wind turbine blades.

By increasing the durability of these composite materials, we make them more sustainable. Wind turbine blades are a good example, but structural composite materials are used in a variety of applications: airplane wings, satellites, automotive parts, sports equipment, and so on. In airplanes, the heating layer also has the advantage of de-icing wings without chemicals. The researchers also explain in their paper that the thermoplastic plastic significantly increases the inherent fracture toughness of components. The energy required for delamination thus increases significantly, meaning that even components without self-healing ability become more robust.