In a breakthrough discovery, researchers from the Justus-Liebig-University in Gießen and the University of Duisburg-Essen have found a cost-effective alternative to using rare and expensive precious metals as catalysts in large-scale industrial processes. These processes cost industries significant amounts of money each year and waste important resources that are needed elsewhere. The researchers have successfully produced a carbonyl complex using the much cheaper semi-metal, silicon, for the first time. This discovery has been published in the scientific journal, Nature Chemistry.

Carbonyl complexes are compounds of carbon monoxide (CO) with a transition metal, such as iron, and are essential in synthetic chemistry and catalysis, such as in the production of fuels. The team, led by Prof. Dr. Peter R. Schreiner from the Justus-Liebig-University and Prof. Dr. Stephan Schulz from the University of Duisburg-Essen, has demonstrated that such complexes can also be produced using main group elements, such as the semi-metal, silicon. This breakthrough is significant for industries in terms of sustainability and cost savings.

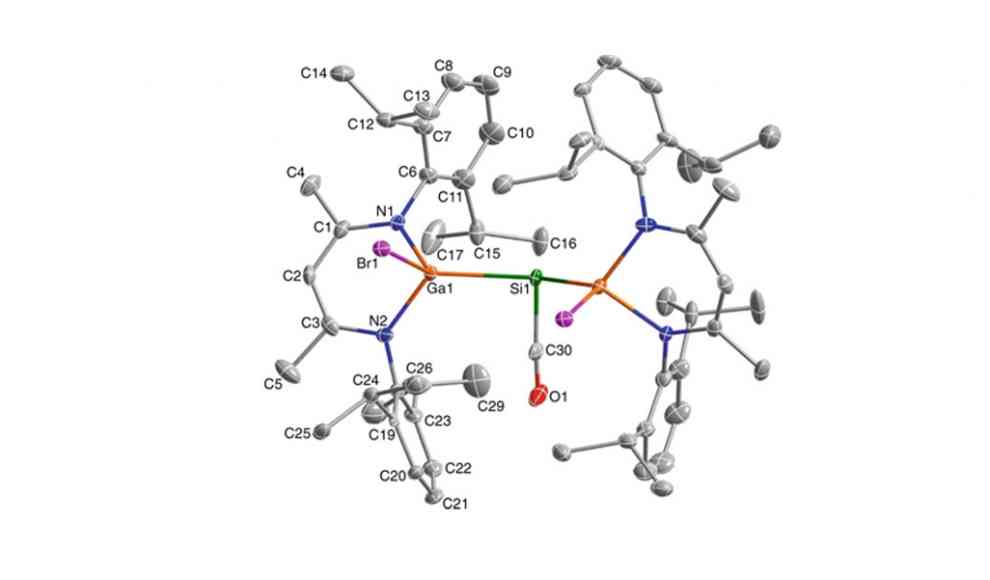

Silicon oxide, commonly known as sand, is a chemical form in which each silicon atom forms four bonds with neighboring atoms. However, in the laboratory, it is possible to force the semi-metal to form two bonds, making it highly reactive. The researchers were able to prove that under certain conditions, the so-called silylene can indeed combine with carbon monoxide to form a stable carbonyl complex. What is remarkable is that this was achieved at room temperature. The researchers hope that the carbonyl complex will soon be used for CO transfer reactions.

This discovery is a significant step towards more sustainable and cost-effective industrial processes. It is also a testament to the ingenuity and resourcefulness of researchers who are constantly seeking new ways to improve our world.