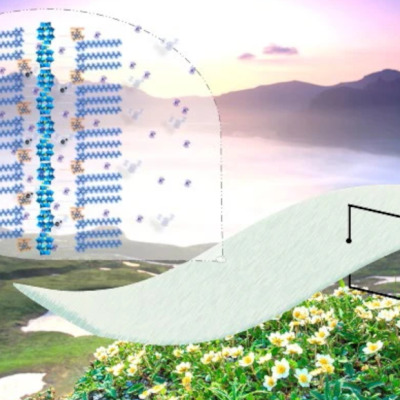

A new recycling process has been discovered that could revolutionize the production of metal hydride storage for hydrogen fuel. Metal hydride storage is a promising solution for storing hydrogen for use in ships, cars, and airplanes, but the production process has been expensive and environmentally damaging. The new recycling process, developed by scientists at the Institute for Hydrogen Technology – Helmholtz-Zentrum Hereon, uses recycled industrial waste to create metal hydrides, eliminating the need for costly and environmentally harmful pure metals. The process has the potential to make the production of metal hydride storage more sustainable and cost-effective.

Hydrogen is a promising energy source for the future, and companies like Airbus are working to develop hydrogen-powered planes. However, storing hydrogen is a challenge, as it is a very volatile gas. Metal hydride storage is a promising solution, as certain metal compounds can absorb hydrogen at moderate temperatures and low pressures. However, the production process for metal hydride storage has been expensive and environmentally damaging, as it requires the use of pure metals that are costly to mine and extract.

The new recycling process developed by scientists at the Institute for Hydrogen Technology – Helmholtz-Zentrum Hereon uses recycled industrial waste to create metal hydrides. This eliminates the need for costly and environmentally harmful pure metals, making the production of metal hydride storage more sustainable and cost-effective. The process has the potential to make hydrogen fuel more accessible and affordable, paving the way for a more sustainable future.